Fresh corn processing line

key word:

Description

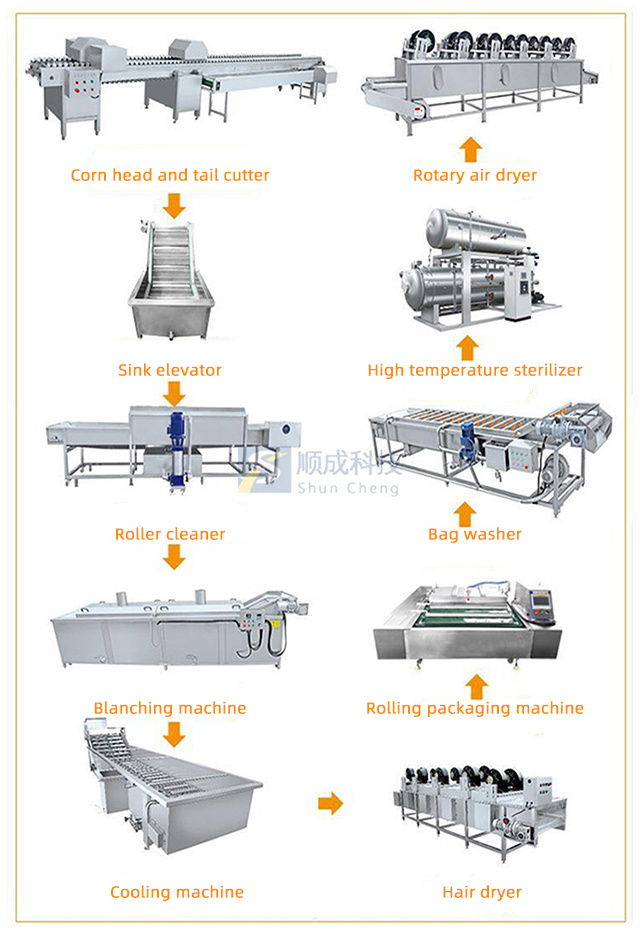

The production line of fresh corn processing equipment is a method of vacuum packaging, high temperature sterilization and room temperature storage, with a storage period of up to one year.

Basic process flow: raw material -→ stripping -→ selection -→ boiling -→ cooling and draining -→ vacuum packaging -→ sterilization and disinfection -→ storage at room temperature.

The complete production line includes: pickling machine, corn cleaning machine, corn cooking machine, corn cooling machine, drain machine, vacuum packaging machine, high temperature sterilization pot, air drying machine and so on.

1, pickling machine: according to the model is divided into two kinds, large and small, can be selected according to the output

2. Corn cleaning machine: It is mainly used to clean the whiskers and bugs on the surface of corn after pickling

3. Corn blanching machine: blanching and fixing the color of corn

4, cooling machine: corn from the digester automatically into the cooling machine inside the cooling operation

5, drain machine: the water on the surface of the corn, to facilitate the vacuum packaging operation is the temperature of the corn itself down to about 10 degrees, to facilitate the next quick-freezing operation

6, vacuum packaging machine: vacuum packaging with processed corn

7. High temperature sterilization pot: While sterilizing the corn packaging bag, the corn is processed and matured

8. Inverted air trunk line: air dry the surface moisture of the sterilized and cooled king rice packaging bag, and can be directly packed after air drying

Related products

Message Consultation

Our staff will contact you within 24 hours (working days), or you can call our service hotline:+86-18946013769

If you have any comments or Suggestions, please leave a message to us!

Harbin Shuncheng Creative Technology Development Co,Ltd

Add:China. Harbin welcome road, high kunlun road no. 10 high open area

Tel:+86-451-84325127

Phone:+86-18946013769

Pay attention to our

Copyright © 2023 Harbin Shuncheng Creative Technology Development Co,Ltd | SEO Tag Business license Powered by :www.300.cn Harbin

黑ICP备16002132号-1 黑公网安备 23010202010265号