Small and medium-sized brewery equipment

key word:

Description

As an excellent manufacturer of self-brewing beer equipment in China, Shuncheng Technology has developed and designed supporting small and medium-sized self-brewing beer factory equipment for small and medium-sized breweries on the basis of learning advanced German technology.

The beer equipment produced by Shuncheng Technology is mainly suitable for the construction of small and medium-sized breweries, draft beer plants, craft breweries, suitable for individual investment, partnership, township enterprises and other investment with an annual output of 300 tons to 5000 tons of small and medium-sized breweries. All equipment adopts standard SUS304 material plate, automatic laser cutting, laser welding, to ensure product quality, saccharation system materials and other adding devices are fully equipped, fermentation system is equipped with sampling, hop dry casting, liquid level detection and other advanced equipment, in meeting the conventional Lager brewing process at the same time, more to meet the current market popular IPA, PA, STOUT and other types of Eyre brewing process!

The whole wheat beer brewed by the beer equipment produced by Shuncheng Technology has high nutritional value and good taste, which is loved by consumers and has significant economic value. Its characteristics are: small investment, quick effect, good quality and low price (only 1/10 of the imported equipment); Long service life, low brewing cost, 1-2 years can fully recover the investment;

The craft beer equipment produced by Shuncheng Technology has a daily capacity of 50L to more than 20T. Products have always been in the international advanced ranks, stable performance, easy operation, not only to ensure the quality of craft beer brewing and pure taste, but also for you to save unnecessary management costs. Equipment specifications: 1000L,2000L,3000L,5000L, 10000L At the same time according to user requirements of the output specifications customized design, production of beer equipment.

Our company has nearly 20 years of equipment production experience and innovation ability, specializing in the design and production of brewery equipment for small and medium-sized breweries. We offer micro beer equipment (mini beer factory equipment) with brewing capacities ranging from 50L to 5000L. Our services include: complete craft brewery equipment, key installation, recipes and techniques for branded beers, staff training and more.

We offer turnkey brewing systems and provide a full range of saccharification systems, hot water tanks, fermenters, clear tanks, water tanks and packaging equipment to suit our customers' craft beer plants. From design and drawing to manufacturing, installation and on-site training, we will always look forward to providing a unique, easy-to-operate craft beer brewing system that makes it easy for your team to brew great beer.

Saccharification system

Fermentation system

CIP cleaning system

Beer factory equipment is generally composed

1. Crushing system (raw material storage and treatment, measurement; Auxiliary materials, malt crusher; Conveying system, control, etc.)

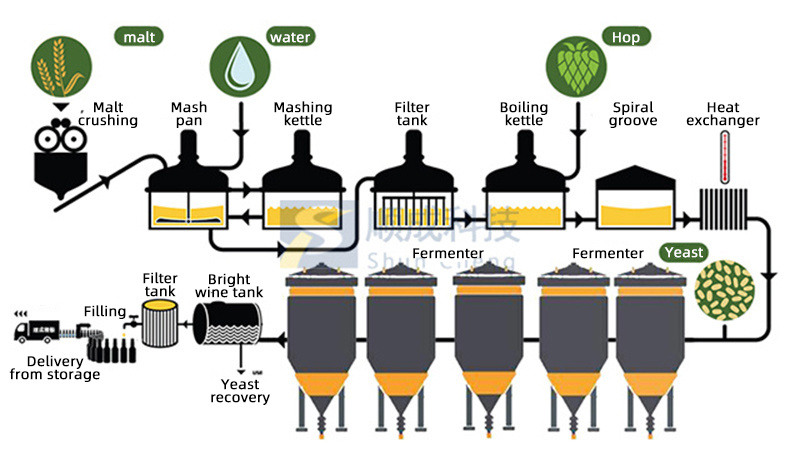

Second, beer saccharification system (mushing pot, saccharifying pot, boiling pot, filter tank, rotary tank system and hot water tank, temporary storage tank, plate heat exchange system, wort oxygenation, testing, conveying system and operating platform and exhaust system; Saccharification control system etc.)

Three, automatic fermentation system (fermenter system, yeast culture, adding system and fermentation control system, etc.)

4. Refrigeration system (ice water, cold water tank, refrigeration unit, etc.)

5. CIP cleaning system (acid tank, lye tank, hot water, sterile water, etc., and cleaning system pipeline)

6. Control system (saccharification control, fermentation control, refrigeration control, CIP control system, etc.)

7, filling and selling wine system (sake, filtration, filling, sterilization, packaging and other systems)

8. Public energy system (pure water treatment, steam, air pressure, carbon dioxide system, etc.)

9. Others (sewage treatment, testing laboratory and other systems)

Installation conditions of beer plant equipment

First, the floor area: according to the size of the equipment model needs 100 square meters to 2000 square meters; Height requirements: the lift of the plant can be defined according to the height of the fermentation and saccharification equipment designed by the output size;

Second, basic requirements: general foundation if the load is not enough, you need to do load-bearing treatment;

Third, the ground wall requirements: the ground of the equipment area should be affixed with floor tiles, and the gutter should be done as required. Tile walls to meet hygiene requirements;

4, power supply line layout: the use of power, the total power between 100-300KW, line layout according to the installation diagram, buried protection iron pipe for threading;

5, water and sewage requirements: the site to provide 4/3 of the upper and lower water pipes, drainage to meet the national standard;

Six, raw material reserve requirements: general reserve 30 days of barley malt, the storage room is required to be dry, the temperature is not higher than 25℃

Related products

Message Consultation

Our staff will contact you within 24 hours (working days), or you can call our service hotline:+86-18946013769

If you have any comments or Suggestions, please leave a message to us!

Harbin Shuncheng Creative Technology Development Co,Ltd

Add:China. Harbin welcome road, high kunlun road no. 10 high open area

Tel:+86-451-84325127

Phone:+86-18946013769

Pay attention to our

Copyright © 2023 Harbin Shuncheng Creative Technology Development Co,Ltd | SEO Tag Business license Powered by :www.300.cn Harbin

黑ICP备16002132号-1 黑公网安备 23010202010265号